Cleaner Linens, Cleaner Planet: Wastewater Recycling for a National Laundry Service

Client: A Large-Scale Commercial Laundry Operator

Location: United States

The Challenge: Industrial laundries are major consumers of water and energy. The wastewater discharged contains detergents, soaps, oils, and grease, presenting a compliance and cost challenge. The client was seeking to reduce its operational costs and improve its environmental footprint by implementing a water recycling system.

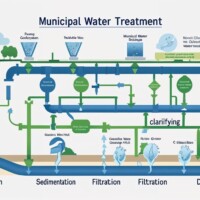

The Solution: The industrial projects company partnered with Ecolab to install a comprehensive water and energy management solution. The system included wastewater filtration and heat recovery technology. The process involved filtering the laundry effluent to remove suspended solids and other contaminants. The treated water was then clean enough to be reused in the washing process.

Furthermore, a heat exchange system was integrated to capture heat from the warm wastewater and use it to preheat the incoming fresh water, significantly reducing the energy required for water heating.

Key Project Features:

- Technology: Wastewater filtration and heat recovery systems.

- Process: Multi-stage filtration to remove contaminants for water reuse and heat exchangers for energy recovery.

- Integration: Seamless integration into the existing laundry operations.

The Outcome: The project resulted in substantial resource and cost savings for the client. By recycling a significant portion of their process water and recovering heat, the laundry facility was able to operate more sustainably and economically.

Quantifiable Benefits:

- Water Savings: A dramatic reduction in freshwater consumption.

- Energy Reduction: Lower natural gas usage due to the heat recovery system.

- Chemical Reduction: Optimized use of detergents and other chemicals.

- Improved Brand Image: Enhanced reputation as an environmentally responsible company.

This example highlights the ability to deliver integrated solutions that address both environmental and economic goals for water-intensive industries.