When you need materials that will withstand the most extreme temperatures, our product range has you covered. Designed to withstand temperatures from 1260°C to 1760°C (2300°F to 3200°F), these firebricks have a wide variety of applications across all heat intensive industries: from industrial kilns and furnaces as back-up insulation to hot face lining in hearth, wall and roof applications.

The high-tech tiles that were used to insulate space shuttles against the heat generated through atmospheric friction were made from a similar material, and have a high tolerance to all kinds of mechanical and chemical stresses.

Applications:

- Furnace And Kilns

- Aluminum Electrolytic Pot Cells

- Carbon Anode Baking Pits

- Petrochemical Heaters

From kilns to smelters and incinerators, nothing could be tougher or safer than our range of refractory firebricks.

Industries:

- Ceramic Industry

- Iron and Steel Industry

- Glass Industry

- Aluminium Industry

- Petrochemical Industry

- Hobby kilns

- Cement, Paper, Pulp & Lime Production

- Incineration, Power Plants and others

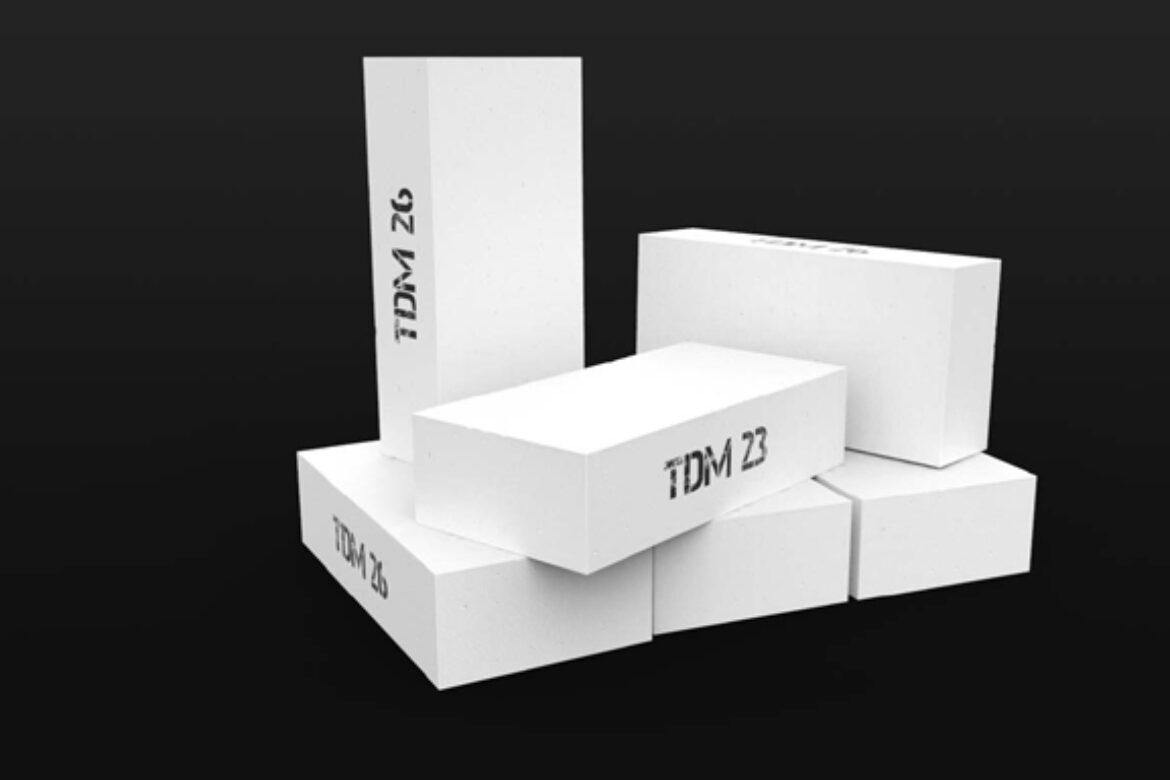

Our refractory fire bricks are manufactured in accordance with the highest global standards of ASTM and ISO, and are available in a variety of shapes and sizes.

A lot goes into finding the perfect product to fit your needs – it should have the right level of porosity and meet your heat resistance requirements. If you would like help with choosing the right product, we can provide you with all the information you need. All you have to do is contact us.

Our Products Refractory Materials